Cracking The Code To Smart Industrial Parks

By SJ Energy & Industrial

Introduction

The rise of the digital economy has prompted countries to review their policies and infrastructure; and has also increased the pressure on companies across all sectors to embrace technologies as well as for workers to learn new capabilities. The adoption of digitalization in the manufacturing sector has further accelerated due to the ongoing Covid-19 pandemic. With technology taking over manual tasks in a more economical and productive manner, many workers performing these roles will find their jobs displaced. The challenge would also be to upgrade the workforce to adopt technology to enhance their skillsets. For the built environment, industrial park developers and policy makers need to adapt their strategy and modus operandi to align themselves with the digital economy. Smart and eco-sustainable industrial parks that can provide a cost-effective, efficient and resilient production space for large pools of local workers can and must become a reality.

Manufacturing as a Key Engine of Economic Growth

Industrial parks can become key drivers of economic activities for developed and developing countries. One distinction of industrial parks over standalone manufacturing facilities is the opportunity for the industrial park developer to curate a mix of like-minded and synergistic industrial clusters, co-located with complementary services and facilities on site to create a true ecosystem; and Jurong Island Chemicals Hub is one such example. Companies on the island enjoy production synergies and efficiencies on the proximity of their value chain and integrated infrastructure such as common pipeline corridors.

Figure 1 Jurong Island Chemicals Hub – Surbana Jurong was involved in the reclamation process to combine 7 islands into one land mass, to form Singapore’s energy and chemicals industry cornerstone with over S$50 billion worth of investments. Singapore is today one of the world’s top exporters of refined oil products, despite having no natural oil or gas resources and limited land.

Starting off on The Right Foot with a Good Development Plan

Industrial park developers are responsible for creating a safe and secure environment for its clients with reliable essential services and infrastructure (such as logistics) so that companies can focus on their core manufacturing activities. Beyond the operational fundamentals, world-class park developers will go one step further to build an estate that supports or champions the causes of companies, such as carbon footprint reduction or circularity in its ecosystem.

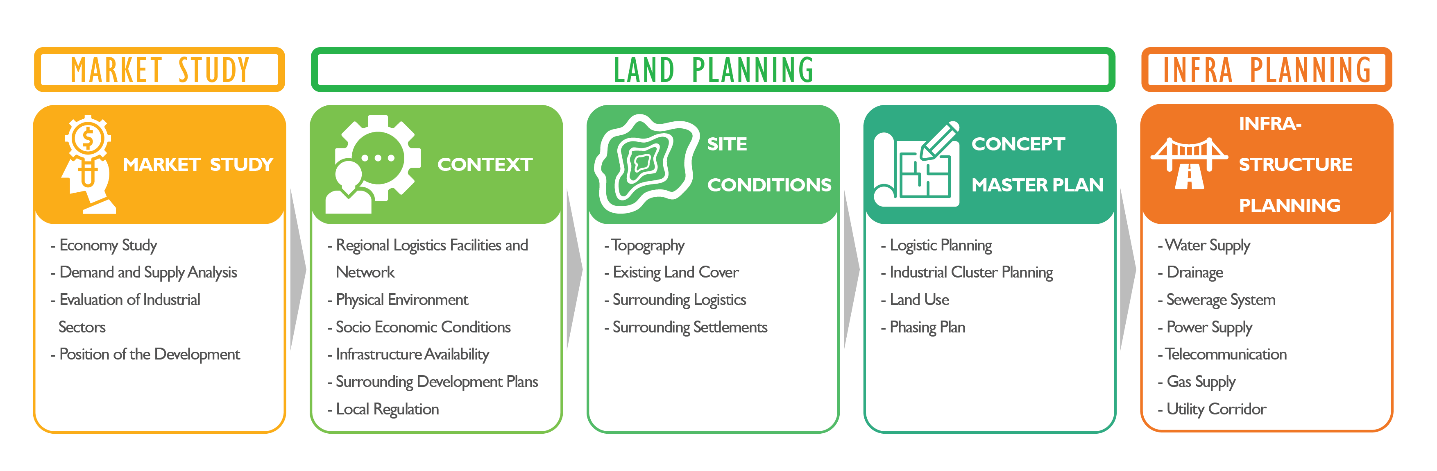

This is achieved through development planning which provides an end-to-end development framework for the building of the industrial park and serves as a blueprint for future expansions. The process begins with identifying the value proposition and concept of the industrial park as well as a comprehensive study of the physical and operating environment. The factors which are assessed include the local regulations, surrounding infrastructure and availability of raw materials amongst other things.

Figure 2 Surbana Jurong’s proprietary approach towards development planning for industrial and petrochemical parks

The COVID-19 outbreak has highlighted the necessity to conduct development planning to build a pandemic-resilient industrial park. Realistically, development planning on its own will not be able to eradicate the effects of an outbreak but when done properly upfront – it can certainly help park operators to better control the situation. Strategic land planning considerations can help industrial park developers segregate different communities and reduce crowding. These include implementing controlled access to the estate, separate entry and exit points for different zones, adequate safety buffers between facilities, as well as accessibility to essential services and amenities. Practising flexible land planning, by strategically setting aside plots of land for temporary uses such as emergencies or companies’ construction laydown requirements would also allow park operators to better respond to unplanned events.

A good development plan will help developers identify organizational needs for the future (anywhere from one to twenty years) and having the blueprint allows them to update their plans more easily as the operating environments and trends evolve.

Importance of Sustainability to an Industrial Park

The effects of Climate Change and in recent times, the Pandemic, have brought Environmental, Social and Governance (‘ESG’) issues to the fore. Increasingly, businesses are beginning to embrace this new consensus. BlackRock, the world’s largest asset manager, released an open letter warning companies that it would be “increasingly disposed” to vote against boards moving too slowly on sustainability[1]. BP has also called time on the Oil & Gas era and asserts that demand for fossil fuels has peaked, with the company pivoting towards Power and Renewables[2]. In a similar vein, TOTAL announced its plans to expand its renewable power generation capacity with the goal of generating 15 to 20% of its revenue from low-carbon electricity by 2040. These changes will have a lasting impact on society and the way businesses are conducted.

In Surbana Jurong’s (SJ) industrial development projects, preparing for future industries, the environment and community take precedence. SJ aims to create resilient spaces that integrate the surrounding landscapes and resources management. Circular production models, which focus on enabling the re-use and recycling of materials, will position the development to better address future resource security issues and result in smaller environmental impacts.

[1] https://www.blackrock.com/uk/individual/larry-fink-ceo-letter

[2] https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/energy-outlook/bp-energy-outlook-2020.pdf

Figure 3 Surbana Jurong partnered with a local aquaculture group to develop the Floating Ponds urban farm concept – an integrated, self-contained fish farming ecosystem, that helps safeguards local food security and resilience in an increasingly urbanised landscape. The 1.5 ha 8-storey vertical fish farm will be the world’s first vertical fish farm and will produce an estimated 2,400 tonnes of seafood a year. The vertically stacked fish raceways help to multiply the production capacity; while its self-sustaining, closed loop farming ecosystem optimises the use of resources – water, nutrients and energy. The outcome is an ecologically sustainable farming model which is modular, scalable and replicable, e.g. an advanced prototype water-reticulation within the tanks will recycle more than 90% of the water, thereby reducing fresh water topping up.

Where possible, energy sources considered for industry should also be as green as possible. This will add to the viability and attractiveness of the development to industrialists who aspire to achieve carbon neutrality in their manufacturing footprint. Ørsted, ranked top in the Corporate Knights 2020 Global 100 Index of most sustainable corporations, is one such organisation that followed through on its commitment to carbon neutrality by making the decisive transformation from one of the most coal-intensive energy companies in Europe a decade ago to focus entirely on renewables today[1]. 23% of the Fortune 500 have made a public commitment to carbon abatement and this number will only increase[2].

Community engagement and inclusiveness is also a critical angle when it comes to addressing sustainable development. Residents in the immediate area surrounding a development will have to deal with increased levels of noise, dust, and other externalities owing to the development. There have been instances where communities’ feedback led to developments being reviewed. The scrutiny on projects is further heightened in the social media era. It is therefore vital for decision makers and park developers to engage the community on the impact of the project; and these efforts can be bolstered with technologies to increase the transparency of developments, such as virtual dashboards detailing construction progress and emission impacts for example.

[1] https://www.corporateknights.com/reports/2020-global-100/top-company-profile-orsted-sustainability-15795648/

[2] https://assets.naturalcapitalpartners.com/downloads/Deeds_Not_Words__The_Growth_Of_Climate_Action_In_The_Corporate_World.pdf

Figure 4 Surbana Jurong’s member company – SMEC is providing community consultation, design and engineering services for the Barcaldine Remote Community Solar Farm project in Barcaldine, Queensland. The project site of approximately 90ha is intended to contribute more than 53,000 MWh of renewable electricity into the national grid each year; and will benefit communities and businesses which currently suffer from poor power reliability and outages due to its remote location.

A Best-in-Class Development Plan Must be Robust & Future-ready

It should address the following:

- Does its physical planning consider environmental factors such as climate change and carbon management?

- How well does it adapt to future scenarios caused by disruptive technologies and digitalisation?

- What are the energy efficiency and risk management strategies?

- How well do the park management processes deal with business continuity and resources sustainability?

- How does the industrial park achieve operational excellence?

Gearing Up for the Future with Smart Industrial Parks

With the COVID-19 pandemic creating a slowdown in demand and forcing manufacturers to reduce the number of workers on site, it is now more than ever an opportune time to explore smarter ways of doing things. Technologies can help reduce worker density and free up the workforce for greater value-added roles in the future.

The objective of a smart industrial park is to achieve a positive outcome for users of the industrial park space and the environment. The concept of a smart and sustainable park is a community of industrial and business activities, planned and built with the environment in mind, that cooperate with each other and the local community to share information, materials, energy or infrastructure thus leading to economic gains, creation of jobs, and improvements in the environment.

Figure 5 Surbana Jurong is developing a concept master plan of a 62 ha digital economy hub in Nongsa, Indonesia. The hub is envisioned to be a digital bridge between Indonesia and Singapore, by anchoring digital-related activities in Indonesia while providing Singapore companies easier access to a growing pool of local Indonesian tech talent. With technology and creative industries as key drivers of Indonesia’s economy, the digital economy hub in Nongsa will contribute directly to strengthening and growing Indonesia’s tech and innovation ecosystem.

The journey towards developing smart parks is not a blind pursuit to increase the number of sensors and equipment, but is an endeavour to identify and deploy the most effective solution for the facility based on its unique conditions and the development’s value proposition. Industrial park developers need to plan for smart park-compatible infrastructure to minimise corrective work later which would be costly and disruptive. One such example is the planning of roads and land plots. As fleets of autonomous vehicles become more commonplace, roads within the industrial parks may need to include dedicated lanes until full autonomy is achieved. Another related trend is vehicle electrification, which would require land and space to be set aside for charging facilities at many locations.

These infrastructure requirements will continue to evolve as the industrial park develops and clients’ requirements change; and having timely access to essential park operations data will help the industrial park developer to make informed decisions. It enables oversight on important processes such as monitoring of key infrastructure within the industrial park and external commercial exchanges with customers, and is the key to smooth operations.

Data plays an integral role in the development of smart industrial parks – namely Sustainability, Logistics Efficiency, Safety, Security and Economic Competitiveness. Most industrial parks are experiencing data overload from various infrastructure and systems; and these operations are often operated in silos. Ideally, these data should be integrated with new data from sensors to conduct analytics of various forms including descriptive, diagnostics, as well as advanced analytics, such as predictive and prescriptive analytics involving machine learning algorithms. The following section will provide some examples to illustrate how data and technologies may be deployed to support the 5 key drivers of the smart industrial park.

Figure 6 Five Key drivers of Smart Industrial Parks (Surbana Jurong proprietary)

Figure 6 Five Key drivers of Smart Industrial Parks (Surbana Jurong proprietary)

Sustainability

Climate change solutions exist today, but require the support of appropriate policy measures to succeed. In the last decade, energy transition has progressed significantly across different industrial sectors, from decarbonising energy sources to increasing operational energy efficiencies. Energy transition can be understood as the global energy sector’s shift from fossil-based systems of energy production and consumption, to renewable energy sources like wind and solar, as well as lithium-ion batteries. This is made possible with advancements in technologies and a societal push towards sustainability, and facilitated by the implementation of regulatory policies. The European Union has taken on a leading role to spur the birth of the world’s first climate neutral continent by 2050 through its newly announced Climate Law which would impose legally binding climate goals on its member countries[1]. In the same vein, China has also pledged to be a carbon-neutral country by 2060[2]. Apart from China, sixty-six countries have signalled their intent to achieve net zero carbon dioxide emissions by 2050[3]; and almost 200 nations have committed to curb global warming by substantially reducing greenhouse gas emissions[4].

Under the United Nations Framework Convention on Climate Change (‘UNFCCC’), the Paris Agreement created a framework for governments and industries to combat climate change and adapt to its effects. While the world still has a long way to go in meeting its targets, it is evident that companies are progressively making efforts to switch to renewables and low-carbon alternatives, as well as cleaner industrial processes, especially as regulatory and investor scrutiny increases.

Industrial parks, especially the petrochemicals sector, are one of the most energy-intensive facilities. Park developers can work closely with the companies on site to progress towards the vision of net-zero emissions. Based on the terrain and natural resources available, park developers can plan and build infrastructure to tap into these renewable resources, be it wind, tidal, solar etc; and deploy sensors to monitor their operating status and energy output to facilitate a seamless switch to an alternative energy source in the event of damage or unavailable energy source (e.g. cloudy day, lack of wind) and overcome its intermittency.

[1] https://ec.europa.eu/clima/policies/eu-climate-action_en

[2] https://www.cnbc.com/2020/09/23/china-claims-it-will-be-carbon-neutral-by-the-year-2060.html?view=story&%24DEVICE%24=native-android-mobile?__source=androidappshare

[3] https://www.straitstimes.com/world/united-states/sixty-six-countries-vow-carbon-neutrality-by-2050-un

[4] https://www.straitstimes.com/world/europe/global-action-plan-to-limit-global-warming-adopted-by-almost-200-nations-after-marathon

Figure 7 Surbana Jurong’s member company – SMEC, has been engaged to provide consultancy services supporting the design and construction of a proposed 300KW micro hydro project in Malawi, covering an area of 7.3ha, and funded by the United Nations Development Programme. A micro hydro project is a hydroelectric power scheme that produces up to 100KW of electricity using a flowing stream or a water flow for isolated communities where an electricity grid is not available.

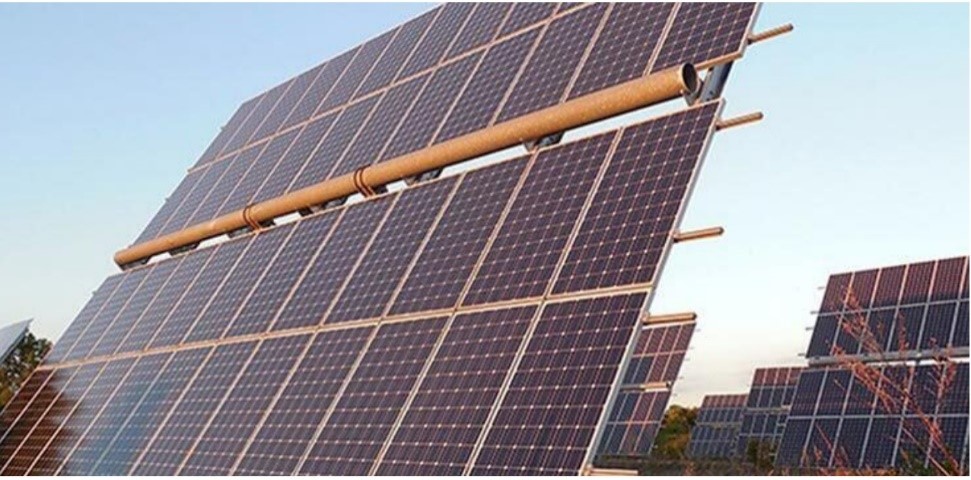

In line with the Paris Agreement, Singapore is continually exploring ways to maximise the use of less carbon intensive fuels and increase energy efficiency. JTC, Singapore’s lead agency for industrial development, has partnered industry players to roll out solar initiatives since 2017, to optimise the use of vacant industrial land and roof space, and to promote the generation and adoption of solar energy[1]. Jurong Island was identified as an appropriate location for the pilot project, due to its availability of large plots of vacant land for the solar PV panels.

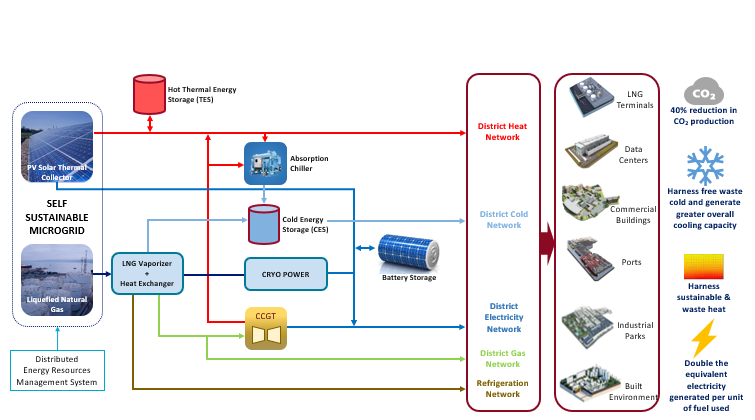

Energy efficiency is an increasingly important contributor to climate change mitigation. At the same time, it helps to reduce the life cycle cost of energy. Recognising this as an opportunity for innovation, SJ has partnered Nanyang Technological University (NTU) to develop and testbed a Cryo-Poly-Generation system, an integrated rapidly deployable and highly energy efficient solution to help meet the growing energy needs of urbanization and industrialization. It is a one-stop solution which encompasses the technologies by which power generation, cold energy harnessing, cold export, cryogenic power generation, city gas generation, steam and hot water (Cryo-Poly-Generation) can be jointly generated from one plant based on the needs of the user. High levels of energy efficiency can be achieved by utilizing cold energy from LNG and waste heat from power generation.

[1] https://www.jtc.gov.sg/news-and-publications/featured-stories/Pages/A-Boost-for-Clean-Energy-in-Singapore.aspx

Figure 8 Surbana Jurong is test-bedding a Cryo-Poly-Generation system which will achieve total energy optimisation enabled by small scale off-grid electricity generation and cold harnessing using LNG.

In addition to monitoring and optimising energy usage and management, effective waste management and disposal are also essential elements of a smart park. With a sizeable population living and working in the park daily, the large volume of domestic and industrial waste will need to be treated, recycled and disposed safely with minimal contamination to the environment. Real-time monitoring of the environment can be achieved through a range of IoT sensors for air, water and soil quality to ensure there is no ground water contamination from the discharge of the factories.

An alternative and innovative approach is the deployment of the Fish Activity Monitoring System (FAMS) by Singapore’s national water agency. The system is equipped with video cameras that have image analysis software to automate and centralise the monitoring of fish activity as an early detection of changes in the quality of the treated water[1].

[1] https://oar.a-star.edu.sg/jspui/bitstream/123456789/1283/1/2008%20SIWW%20AFAMSfEDoWC.pdf

Sustainability – Points to Consider:

- How to motivate every industrialist to champion sustainability in their operations?

- What aspects of sustainability make the most sense?

- How does the park owner / developer / operator play a value-adding role?

- How to set park-level goals?

Efficient Logistics

Park operators can leverage multi-sensory input, such as closed loop sensors on the ground and artificial intelligence (AI) based video analytics, for comprehensive and real-time monitoring of traffic conditions within the estate. With these data, park operators can understand the movement of people, goods and vehicles – how the transportation system is being utilised, how and when congestions occur, and even the number and type of vehicles travelling. These solutions will support park-level planning of the transportation network. With this, park operators can ascertain if there is a need to widen the roads, adjust the number of lanes, or create a dedicated cycling lane – and these are all decisions which would not have been easy to make in the absence of the traffic data.

Underground systems such as the tube capsule may be deployed for freight transport in congested urban areas, covering up to 150km and freeing up precious surface land for higher value-added activities. Automated capsule systems are typically used for pallet sized cargoes and containers.

Efficient Logistics – Points to Consider:

- How well do we understand the supply chain of the industrialists?

- Is the transportation plan future-ready?

- How to build a robust logistics ecosystem within the park?

- What does the risk management playbook look like?

Safety

The ability to monitor and trace the movement of people has been pivotal in helping to stem the spread of COVID-19. Governments worldwide have been quick to launch various digital tools to achieve this end, and industrial park operators have a similar responsibility if they wish to maintain a pandemic-resilient industrial park.

Figure 9 To help minimise the risk of infection spread at project worksites, Surbana Jurong started trialling a wearable contact tracing device at one of its construction worksites. The technology allows proactive tracking of interactions and movements which could possibly shorten the contact tracing process to under 2 hours and minimise disruptions to operations. This is especially useful at construction sites where there is usually a high volume of movement by different groups of contractors and suppliers.

Ensuring safe manufacturing practices is the responsibility of individual companies. However, it is also crucial for the park operator to have a system-level overview of safety considerations for long-term land planning and emergency response, particularly for petrochemical parks which involve hazardous activities. This can be achieved through a centralised risk assessment system, which integrates the quantitative risk assessments from upcoming and existing facilities, overlaid against GIS data, and with capabilities that include understanding the harm footprints, individual risk contours, and conducting consequence modelling. Data from sensors can be deployed at sensitive locations, such as near or within hazardous facilities and worker dormitories, to measure environmental conditions including wind direction, humidity, air quality and contaminants. The data is then channelled into the blast and plume simulation engines to help the park operator estimate the likelihood of incidents and to understand how incidents might occur and spread. Such information is critical during emergencies to help the park operator decide when to trigger an evacuation, and to coordinate multi-agency, multi-disciplinary emergency response efforts.

As 5G networks with its faster speeds, greater capacity and reduced latency gain traction, we can expect new and improved services especially in the areas of virtual reality, IoT and AI. An example is the mixed reality maintenance of complex machinery and equipment by experts stationed overseas, which will strengthen workplace safety by reducing manual interference and support flexible remote work arrangements for a more pandemic resilient workplace.

Safety – Points to Consider:

- How to inculcate a safety mindset in everyone?

- How good are we at detecting threats to safety?

- Does the hazards management framework support the growth of the park?

Security

Having control and knowledge over who, what and when people, vehicles and goods entering and leaving the park is fundamental to ensure the security of the park. This is also a top priority for industrial parks with high risk activities (such as petrochemical parks) or high value products. Pre-screening of people and vehicles, and the use of biometrics such as fingerprint and face recognition, Automatic Number Plate Recognition (ANPR) and under carriage scanners for vehicles, will collectively reduce the risks of unauthorised access to the industrial park premises, and help to monitor the checkpoint to mitigate cumbersome manual checks that are subject to human error.

It is also essential to deploy a platform of video analytics, which will allow each video stream to be processed with different analytics to generate different alerts for different stakeholders depending on the park’s changing security posture. Together with physical access control and video analytics, the park developer can help ensure a secured and controlled environment to minimise disruptions to the supply chain and at the same time allow companies to have assurance on the timeliness of delivery and quality of goods.

In addition to physical security, cyber security is another aspect which should not be neglected. Particularly as the cyber-attack surface has increased with the exponential growth in implementation of IoT sensors integrated with SCADA, Industrial Controls Systems (ICS), IT systems and cloud containers in industrial parks. As a responsible smart park operator, it is crucial to continually monitor and have the resources to conduct a coordinated response to known and previously unknown cyber threats; and these can be achieved through a cyber security operations centre.

Security – Points to Consider:

• Is there an emergency response plan for the park?

• What model is used for scanning and evaluating technology options?

• How to achieve a balanced view in line with the park’s risk profile?

Economic Competitiveness

A command centre is essential for achieving situation awareness in the industrial park and responding with appropriate resources. The command centre is akin to the nerve centre for the park operator, which consolidates all the important data feeds for a holistic view of the park operations 24/7, 365 days a year, thereby enabling quick response to incidents such as traffic accidents, or pipe leaks. The command centre can also serve as the coordination centre with external agencies for firefighting and crowd controls, etc, when needed.

With an aggregated platform to integrate all the sub-systems within the industrial park, from security applications, building management systems to the communicable devices, the park operator will be able to effectively monitor and control these applications and equipment from a single unified surface, respond faster to situations, strengthen security and access control, and lower operational costs. Ultimately, the outcome should be a more controlled park environment with smoother operations, and a more economically competitive industrial park.

Ningbo Petrochemical Economic & Technological Development Zone is one such industrial park that has invested heavily in various systems to monitor and manage various domains of its park operations and is actively utilising data to monitor its key equipment and processes. In 2019, the park was ranked 2nd in the country’s top chemical parks and is a forerunner in establishing smart and green practices in China[1]. Closer to home in Singapore, Hyundai held a virtual groundbreaking ceremony in October 2020, which will produce electric vehicles, and test-bed various smart and advanced manufacturing systems such as IoT and artificial intelligence. The new multi-function facility is expected to generate hundreds of new jobs[2]. These examples suggest that, generally, companies that have invested in and continue to invest in improving their management of existing data, growth of usable data, and usage of data analytics, will continue to thrive even in times of economic uncertainty.

[1] https://cs.zjol.com.cn/zjbd/nb16504/201905/t20190524_10188819.shtml

[2] https://www.straitstimes.com/singapore/transport/carmaking-returns-to-singapore-with-new-smart-plant-in-jurong

Economic Competitiveness – Points to Consider:

- What is best-in-class park management?

- How does responsiveness translate to tangible benefits to industrialists?

Continuous Adaptation

Recent events have driven home the point that we live in a Volatile, Uncertain, Complex and Ambiguous (VUCA) world. The COVID-19 pandemic, financial crises, climate change, tightening emissions standards, and geopolitical tensions are just some of the events in the past decade that highlight how globalisation can and will continue to disrupt all aspects of our lives. The COVID-19 pandemic is a textbook example of how companies were caught off-guard by the pandemic and scrambled overnight to respond to sudden lockdowns and disrupted supply chains. While no one could have anticipated the outbreak, companies could have mitigated the impact to some extent if they had identified and prioritized mission critical functions and developed business continuity plans beforehand, as part of a Pandemic Influenza Risk Management Plan. Industrial park developers that seek to create an operationally resilient ecosystem, and build deeper relationships than that of a straightforward landlord, should also engage the companies to spearhead and develop business continuity measures at a park-level such as ensuring the delivery of food supplies and clear transportation networks.

Technological advances in an increasingly interconnected world have also heightened the pace of change and complexity of doing business. Without knowing what changes to expect, how can companies set themselves up for success? Strategy is, by definition, all about evaluating the myriad options to derive the best decision. In our VUCA world, this means leveraging technological enhancements to interpret the constant stream of data and continually adapting the strategy.

We need to consider ongoing and anticipated changes in the environment and in our competitors, what needs to change and the trade-offs, how to change, and how each decision will ultimately fit in with the company’s strategic priorities. Flexibility and agility do not mean continually changing strategy, but rather – possessing the acumen to perceive when and how to adapt.

Conclusion

Today, there is no single universally agreed upon definition of what makes a development ‘smart’. If everyone is doing the same new thing, is that still considered ‘smart’? In our opinion, smartness is relative to the socio-economic-environment concerns and challenges of the day, and it hinges upon nimble strategic adaptations – be it quick adoption of emerging technology or even a review of existing processes and organisational set up to gain competitive advantage over competitors.

Unfortunately, this means there is no one-size-fits-all solution that will guarantee the success of any or all smart industrial park because each one faces a different set of challenges and opportunities; and circumstances, technology and competitor adoption change rapidly.

Figure 10 Surbana Jurong provided multi-disciplinary consultancy services as well as sustainability and resiliency solutions for Singapore’s first one-stop poultry processing hub. Named JTC Poultry Processing Hub, the 8-storey multi-tenanted development is designed to house poultry slaughtering and processing establishments, featuring fully-automated and high-speed slaughtering lines that are shared by multiple companies. This will enable closer collaboration and sharing of resources among the establishments. (Photo provided by JTC)

The real (if not so exciting) secret to cracking the smart industrial park code lies in the knowledge and experience we have accumulated from having worked on several cutting-edge projects locally and globally for clients from various industry sectors in more than 40 countries. With our comprehensive suite of multi-disciplinary, best-in-class solutions across the full value chain, we are well-equipped to help industrial park developers craft targeted strategies and processes that will enable them to continuously ‘smart-ify’ their industrial parks appropriate to their unique challenges.